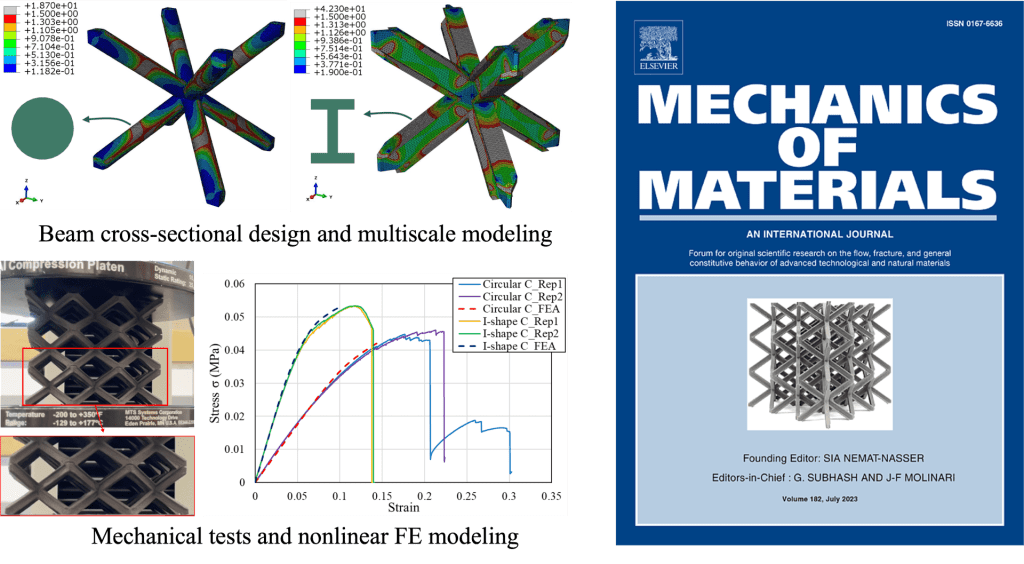

New class of beam lattices

Emerging lattice metamaterials, such as beam-based lattices, can be designed with unprecedented material properties. Leveraging an advanced multiscale structural modeling approach, PI Dr. Liu has designed a new class of beam lattices with much-improved mechanical performance, such as high stiffness/strength-weight ratio and energy absorption, compared to existing beam lattice designs. In collaboration with Dr. Yiran (Emma) Yang from the IMSE department, the team has successfully fabricated I-shaped beam lattices, demonstrating significantly improved stiffness/strength-weight ratios. Ongoing work focuses on crafting innovative designs for this novel class of beam lattices. These innovative beam lattices hold the potential to supply next-generation lightweight materials for various defense applications.

Reference:

- Liu, X., Kobir, M.H., Yang, Y., Jiang, F. and Kothari, T., 2023. Improving stiffness and strength of body-centered cubic lattices with an I-shape beam cross-section. Mechanics of Materials, 182, p.104665. DOI: 10.1016/j.mechmat.2023.104665.

- Kobir, M.H., Liu, X., Yang, Y. and Jiang, F., 2022, June. Additive Manufacturing of Novel Beam Lattice Metamaterials With Hollow Cross-Sections Towards High Stiffness/Strength-to-Weight Ratio. In International Manufacturing Science and Engineering Conference (Vol. 85802, p. V001T01A027). American Society of Mechanical Engineers.

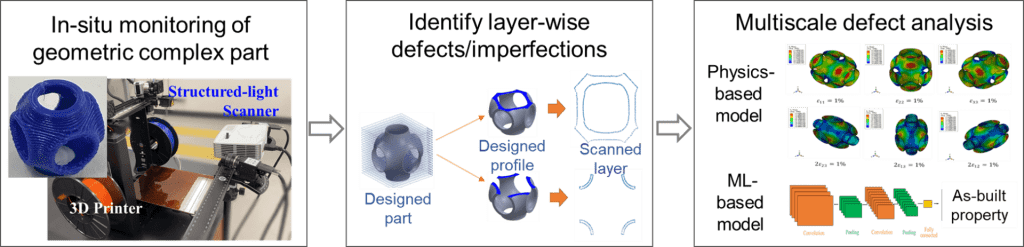

Manufacturing defect analysis

Process-induced defects are ubiquitous in manufacturing due to various sources, especially when fabricating geometric complex parts. By integrating multiscale modeling, machine learning, and in-situ monitoring, PI Dr. Liu is collaborating with Dr. Chen Kan form the IMSE department to develop ultra-efficient models to connect the as-manufactured features to the effective material properties and performances in a real-time fashion. The goal is to thoroughly understand the process-structure-property-performance relationships of mechanical metamaterials with complex topology, and subsequently develop a real-time performances evaluation system towards reduced-defect and better-quality products.

Reference:

- Yang, Y., Kan, C. and Liu, X., 2022 Point cloud based online detection of geometric defects for the certification of additively manufactured mechanical metamaterials, Journal of Manufacturing Systems, 65, p. 591-604. DOI: 10.1016/j.jmsy.2022.09.011.

- Liu, X., Kan, C. and Ye, Z., 2022. Real-time multiscale prediction of structural performance in material extrusion additive manufacturing. Additive Manufacturing, 49, p.102503. DOI: doi.org/10.1016/j.addma.2021.102503